Dam Buster's amazing sumps revolutionize another critical area of roof drainage

Free flow Dam Buster Sumps are fully engineered and certified devices which don't require complex calculations to size. They also don't require the water level to back flow and rise in the box gutter before they operate in the overflow condition. Like all Dam Buster devices, they are selected based on flow rate in litres/second.

Our revolutionary design makes these sumps an absolute breeze to select and install when compared to the very complex ‘Sump / high capacity overflow’ device in AS/NZS 3500.3. Dam Buster sumps can also be safely used in lieu of the code specified Sump / side overflow devices.

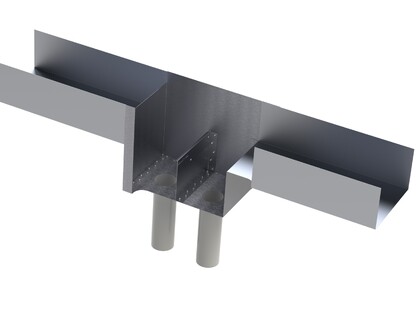

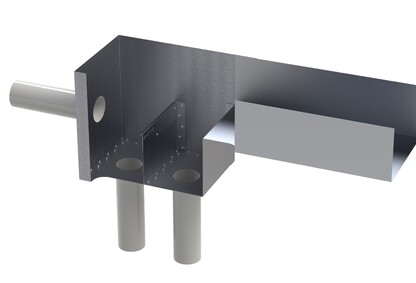

Dam Buster free flow sumps come factory made in 100mm size increments to suit all sizes of box gutter between 200mm and 600mm. They can be easily fitted to virtually any box gutter, whether new or retrofit and are part of the integrated Dam Buster roof drainage system.

How They Work: If the first chamber of the Dam Buster free flow sump is overwhelmed, or if the first chamber blocks with debris, the water just crests the internal weir and flows into the second chamber where it is safely disposed of via a second (overflow) down pipe to atmosphere as required by the code. An additional overflow to atmosphere can also be fitted to the end of the second chamber if required, providing multiple redundancy.

Pick Your Size: You can find the selection tables in our Product Technical Statement which is available from Technical Downloads

Physical external product dimensions can be found HERE.

Unlike existing sumps made by all other manufacturers, box gutters discharging to a Dam Buster Sump are designed for genuine ‘free flow’ in accordance with Figure I1 of AS/NZS 3500.3 in both the normal and overflow conditions. This also means the box gutter can be designed independently of the sump i.e similar to the rainhead.

Please Contact Us for more information.

Sumps are available in Colorbond, Zincalume, stainless steel, Colorbond Ultra or any other suitable sheet metal material. They can also be easily powder coated if required.

Potential uses of these amazing devices are limited only by the imagination, but include:

They easily replace standard code sumps - Dam Buster sumps are much simpler, require no custom design or certification, perform far better and are also potentially a lot cheaper

Multiple sumps can be used along a single box gutter, including over very long distances. Extra redundancy can easily be built in along the length of the gutter by cutting down the end wall of the sump overflow chamber/s in accordance with the Dam Buster Installation Manual.

Installing the sumps back to back to double the capacity.

They provide extra versatility in roof drainage and building design. As an example, they can be installed where a rainhead cannot be used due to the presence of a window or door below; in this case both the normal and overflow downpipes can potentially also be concealed and directed internally away from the sump location.

NOTE: Requirements vary from state to state but generally a Performance Solution is required for installation certification purposes of Dam Buster free flow sump devices; Documentation to assist the development of a suitable Performance Solution can be found here at Technical Downloads